Researchers developed a novel technique called “atomic spray painting” to enhance potassium niobate’s properties for greener and more efficient technologies.

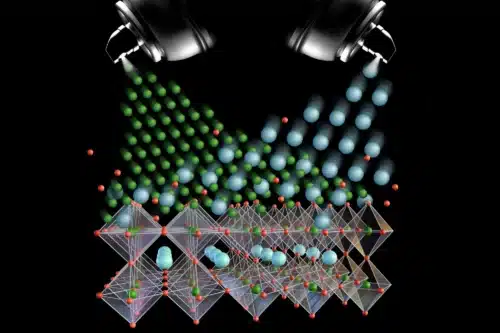

In the latest research scientists from Penn State Department of Materials Science and Engineering used molecular beam epitaxy (MBE) to strain-tune potassium niobate—a key material in advanced electronics. By adjusting the material’s atomic structure, they achieved precise control over its thin-film properties, generating new possibilities in green tech, quantum computing, and space exploration.

Strain tuning involves stretching or compressing a material’s atomic structure, altering its characteristics. The team employed MBE to deposit atomic layers onto a substrate, enabling the creation of strain-tuned thin films of potassium niobate with exceptional accuracy. “The technique is like spray-painting atoms onto a surface,” explained Venkatraman Gopalan, professor and lead author of the study.

This method could attract industries requiring materials that endure extreme conditions, such as aerospace, quantum computing, and consumer electronics. Potassium niobate’s enhanced ferroelectric properties make it appealing for manufacturing high-temperature memory storage and energy-efficient devices. “Ferroelectrics are like mini batteries charged by nature,” Gopalan explained, highlighting its pivotal role in technologies like ultrasound equipment and optical systems.

The process also leverages a substrate template to induce strain. Co-author Sankalpa Hazra noted that even a slight strain of 1% can generate substantial pressure, significantly enhancing potassium niobate’s ferroelectric properties. Notably, the material’s performance remained stable at extreme temperatures, withstanding over 701.85°C.

What sets this study apart is its environmental implication. Potassium niobate is lead-free, unlike many high-performing ferroelectric materials that raise toxicity concerns. “This positions it as a strong, safe alternative to lead-based materials,” Hazra emphasised.

Future efforts aim to integrate these thin films onto silicon substrates for practical applications. With its potential to upgrade personal devices, space exploration, and green technologies, strain-tuned potassium niobate may define the next generation of sustainable, high-performance electronics. “This material could redefine eco-friendly tech,” Gopalan remarked, signalling its broad appeal across diverse technological sectors.