New technology is becoming increasingly prevalent in a multitude of settings, including in the elevators and escalators that all of us use to reach the floors of commercial buildings, shopping malls, apartment complexes, and condominiums. It is estimated that there are nearly 20 million elevators and escalators operating worldwide, with a substantial increase in the number of installations. In the year 2021, the quantity of new installations exceeded one million units. Market drivers include the growth in urban population, which requires more apartment buildings and office buildings. Other drivers include adding intelligent sensing and wireless connectivity to reduce unplanned downtime and increase user convenience.

The need to reduce power consumption compels innovation. New, improved motor drives and electronics can result in a notable reduction in energy consumption and costs. For example, LED lighting reduces the power required for elevator illumination, and occupancy sensors shut down power when the elevator is idle. It is of particular significance that regenerative motor drives can reduce energy consumption by up to 35%. This is achieved by capturing energy when the elevator travels down and transferring the power to other building systems.

In addition to ensuring high reliability for a product that must be operational 24 hours a day, seven days a week, the additional electronics challenge designers to protect sensitive circuitry from external environmental threats. Furthermore, designers must consider ways of reducing energy consumption compared with older elevator designs.

This article is concerned with safe and efficient elevator design, providing design engineers with solutions to protect against overcurrent conditions, overvoltage transients, overtemperature conditions, and electrostatic discharge (ESD). Moreover, the article recommends components that can improve the efficiency of the design and reduce energy costs. These recommendations will enable designers to develop robust, reliable, safe, and energy-efficient elevators.

Designers must ensure reliability for the elevator power control panel and the elevator cabin. The following paragraphs will address making these two elevator elements robust to electrical hazards and energy efficiency.

Recommendations for a robust, energy-efficient elevator power control panel

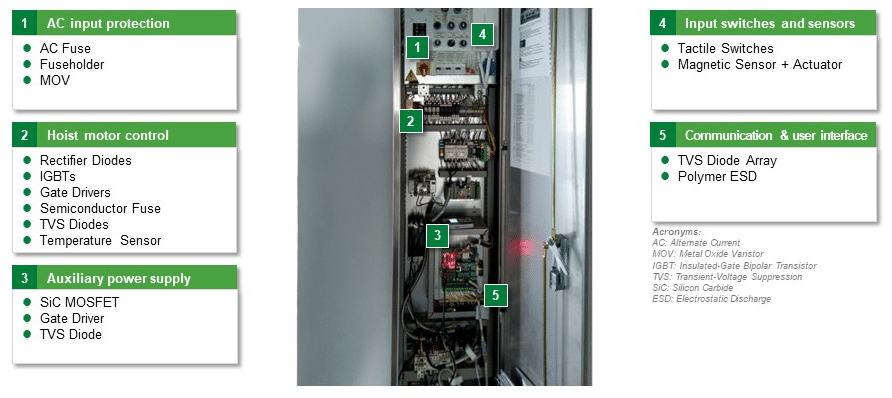

Let’s start with the design of the elevator power control panel. The example in Figure 1 shows an elevator power control panel. The blocks around the control panel highlight the recommended components that provide circuit protection, sensing, and efficient control. The control components can contribute to reduced energy consumption and energy savings.

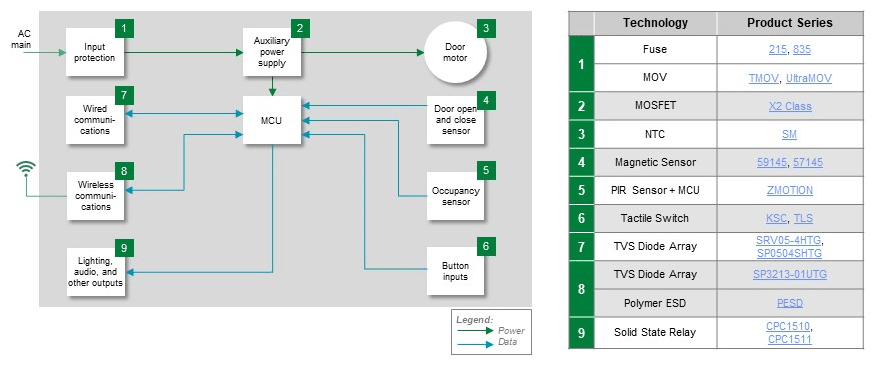

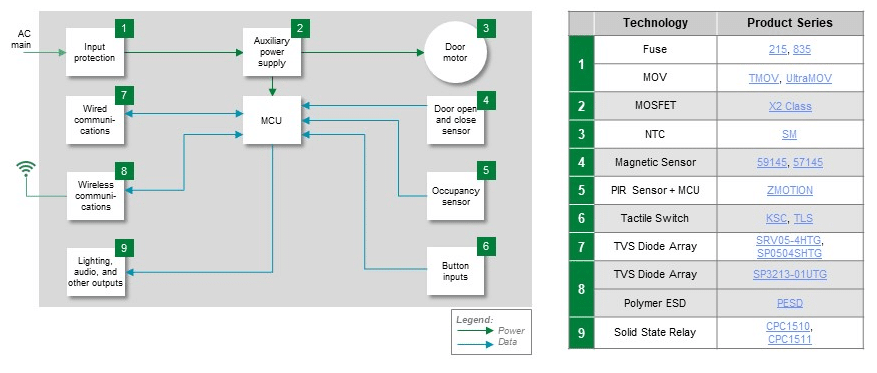

Figure 2 provides more detail and illustrates a block diagram of the elevator power control panel. The adjacent table lists the components required by the circuit blocks for protection and energy efficiency.

Since ensuring a reliable elevator design is essential, the initial discussion will focus on protecting the control panel from potential failure due to electrical hazards. These hazards include overcurrent, overvoltage, overtemperature conditions, and ESD.

Protecting the control panel circuitry from overcurrent and overvoltage conditions

Input Protection block

The Input Protection block is connected to the AC mains. The AC mains have the capacity to supply high current to a load, such as an elevator control panel, if an overcurrent condition occurs. Furthermore, high-power voltage transients induced on the AC power line by lightning and large motors energizing and de-energizing can strike the Input Protection block of the control panel.

For maximum safety, protect the control panel from the high current capacity of the AC power line with a fast-acting fuse. To ensure the fuse can operate properly, select a fuse with a voltage rating exceeding the maximum possible voltage of the AC power line. Also, choose a fuse with a high current interrupting rating so the fuse will safely open and not allow arcing during an overcurrent condition. Support the fuse in a fuse holder with similar ratings as the fuse so as not to degrade fuse performance.

Consider a MOV for safely absorbing a voltage transient propagating on the AC power line. Investigate a MOV that can withstand at least a 6000 A transient pulse and at least 400 J of transient energy. Designers can ensure the MOV is functioning properly by selecting a MOV with an internal thermal element that will open the component if the transient duration causes an overheating condition.

Auxiliary Power Supply block

The Auxiliary Power Supply converts the AC line voltage to DC for powering the Programmable Logic Controller (PLC) and the other DC-powered blocks. Designers can protect this circuit from any portion of the voltage transient that passes through the Input Protection block with a transient voltage suppressor (TVS) diode. TVS diodes protect the semiconductors in the Auxiliary Power Supply and the downstream current blocks. TVS diodes have response times under a nanosecond. Look for TVS diodes that can safely absorb at least 200 W of transient power.

Inverter block

The Inverter provides the power to drive the AC hoist motor. Consider using a high-speed fuse and a TVS diode to protect the power semiconductor components from motor-induced transients. Select a fuse with a low I2t characteristic to minimize heat energy from impinging on the components. Add a TVS diode to clamp the voltage transients to safe levels. Ensure the TVS diode can safely absorb as much as 600 W of peak pulse power.

Providing overtemperature protection

In the Inverter circuit block, it is essential to monitor the temperature of the high-power semiconductors in order to prevent a thermal runaway condition. Look for NTC thermistors with a fast thermal response. Ensure high reliability with thermistors that are hermetically sealed and can operate up to 220° C.

Ensuring ESD protection

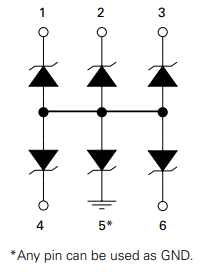

The circuit blocks that interface with the external environment, such as the User Interface and the Wireless Communications interface, are susceptible to ESD (Electrostatic discharge). TVS diodes, with their ultra-fast response times, are excellent choices for the suppression of ESD from either a user or the external environment. For the User Interface, consider a TVS diode array, as shown in Figure 3, to protect up to five data lines with a single, small component. Use a TVS diode with IEC 61000-4-2 compliance to allow adequate ESD absorption.

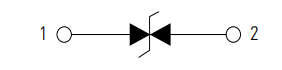

In the Wireless Communication block, which transmits elevator status information, options for ESD protection include a TVS diode or a polymer ESD suppressor. Figure 4 shows a bidirectional TVS diode for protecting against ESD of either polarity. If using a TVS diode, select based on the diode capacitance to minimize distortion to the transmitted signal. TVS diodes with capacitances under 1.0 pF are available. The alternative, the polymer ESD suppressor, can withstand a higher ESD strike, up to 30 kV, and can have capacitance under 0.1 pF. Figure 5 shows an example schematic of a polymer ESD suppressor.

Incorporating reliable performance

Use long-life, tactile switches in the Floor Call buttons circuit. The switches should have sufficient haptic feedback, so users can feel the button has been activated. Choose switches with a rated life of at least 200,000 operations and be aware that switches with a rated life of up to 10 million operations are available. Investigate switches with hermetic sealing and corrosion resistance properties in order to further enhance reliability.

The Floor Indicator Sensor block detects when the elevator reaches the level of a floor. A magnetically operated proximity sensor can serve the requirement. Choose a hermetically sealed sensor for long life and maximum reliability.

Maximizing energy savings

Elevators consume a significant quantity of energy, and energy-efficient elevators can save a building owner a substantial amount of utility costs. The more energy efficient the elevator, the greater the competitive advantage it can have in the market. Designers are tasked with the challenge of maximizing energy efficiency.

The Rectifier Block is a circuit that offers the opportunity to reduce power consumption. Rectifier diode packages are available that have both low forward voltage drop and low leakage current. Packages are also available with a control circuit that can permit returning energy to the power grid utilizing energy recovered from the braking action of the hoist motor.

The Auxiliary Power Supply is another circuit that can become more energy efficient. Using a switch-mode topology with SiC MOSFETs, the designer can achieve a high-efficiency AC-DC converter. Use a SiC MOSFET with low RDS(ON), low gate charge, and low output capacitance to minimize power loss in the MOSFET and allow high-frequency switching.

Optimize the efficiency of the MOSFET with a gate driver chip, which provides the following:

- Quick turn-on and turn-off signals to control the MOSFET,

- A negative gate bias circuit enables fast turn-off of the MOSFET, and

- More energy savings and simplified circuit complexity with a single package.

The Gate Driver circuit block controls the power inverter semiconductors. Use a high-power gate driver. Dual gate driver chipsets can source as much as 30 A peak current and operate on voltages from 5 V to 35 V. Also, look for gate drives that consume the least power with supply currents of around 10 µA.

The fourth circuit where designers can save energy is the Inverter circuit. In this circuit, designers can employ IGBT power transistors for power delivery to the motor. Ensure maximum drive efficiency by considering IGBTs with low VCE(SAT) and low gate charge.

Recommendations for a robust, energy-efficient elevator cabin system

With the power control panel optimized for robust protection and energy efficiency, the designer needs to complete the elevator design work by applying the same development considerations to the elevator cabin. Figure 6 shows an example elevator cabin, and the surrounding text blocks indicate where protection and energy-saving technology can apply. Figure 7 shows a block diagram of the cabin system. The adjacent table lists the recommended components that provide the cabin system circuitry protection, safety, and energy efficiency.

Protecting the elevator cabin

To protect the cabin control system from AC power line-induced overcurrent and overvoltage conditions, use a fuse and a MOV in the Input Protection circuit. Unlike the control panel, consider a time-lag fuse in the Input Protection circuit of the cabin control system. A time-lag fuse will avoid nuisance shutdowns resulting from inrush currents.

Ensure the door motor is protected from overheating. Use an NTC thermistor to monitor the temperature of the door motor.

The Wired Communications and Wireless Communication circuits should use TVS diode arrays to protect the semiconductor components from ESD strikes. Like the power control panel Wireless Communications circuit, designers can choose a polymer ESD suppressor rather than a TVS diode.

Incorporating reliability and safety

In the Lighting, Audio, and Other Outputs circuit block, consider optically isolated, solid-state relays to protect users and service personnel from high voltage circuits. Look for relays with active current limit and thermal shutdown protection.

Consider using a magnetic sensor to detect the position of the door in the Door Open and Close Sensor circuit. Hermetically sealed sensors offer extended life for greater reliability.

In the Button Inputs circuit, use a long-life switch identical to the switch recommended for the Floor Call circuit in the power control circuit. Long-life tactile switches can have ratings as high as 10 million operations. Also, consider switches that have options for illumination and are sealed from water and dust ingress.

Designing in energy efficiency

There are opportunities for improving energy efficiency in the elevator cabin system. Maximize efficiency in the Auxiliary Power circuit by using power MOSFETs which allow a switch-mode supply to have a high switching speed. High-speed switching enables the use of smaller inductive components, which can save circuit board space and cost.

A motion detector circuit in the Occupancy Sensor circuit allows detection and notification that people are in the elevator. Designers can use compact motion detectors with integrated microcontrollers to simplify detecting motion and to process the data. Data from the circuit informs the cabin system microcontroller when the elevator’s power circuits can shut down.

Achieving a robust, reliable elevator with energy efficiency

The design of a reliable, robust, safe, and energy-efficient elevator project poses many challenges for the design engineer. This article offers suggestions for components that can help the designer achieve these objectives.

It is beneficial for designers to have access to the expertise of component manufacturer’s application engineers, who can save development time and costs. They have the expertise to offer technical services, including:

- Cost-effective component selection

- Guidance on applicable safety standards

- Pre-compliance testing (provided by some component manufacturers) to help identify issues before submitting a design for formal compliance testing.

Using the recommended protection, control, and sensing components will ensure a reliable, safe, and energy-efficient elevator

About the Author: Barry Brents is a Field Application Engineer at Littelfuse. He is a former U.S. Navy nuclear submarine officer and a licensed professional electrical engineer in Colorado and California. He has been with Littelfuse for 35 years (including acquisitions), and his current responsibilities include technical support, design assistance, and training for customers and salespeople. Barry received his B.S.E.E. from Texas Tech University.